2025 in review: new packaging, tariff troubles, and a Linux shoutout

All in all, 2025 was a very eventful year… but we barely touched our social media and email list, so you may not have known it. Here’s what we’ve been up to over the past 12 months.

Linux mailing list

It started off with something completely unpredictable: in January, we got a shoutout from Linus Torvalds, the creator and namesake of the Linux operating system, on the official Linux developers mailing list. Linus is one of the most influential software engineers alive, and someone I’ve respected since I first started programming in middle school, so it was a pretty surreal full-circle moment for me personally.

He built several of our kits over the holiday break (“LEGO for adults”, in his words) and since he doesn’t play guitar, he offered to give away his builds to anyone who had contributed to the Linux kernel throughout 2024.

Since then, he’s gotten into designing his own circuits. He created a Github repository with some of his own KiCAD designs and project wrappers, mostly analog but getting into some digital as well, with a several updates over the last few months. He also went on Linus Tech Tips a few weeks ago, and briefly shows one of his designs at 11:06 in the video:

New kit packaging

This fall, we transitioned to a new type of packaging for our kits. If you ordered anything for our Black Friday sale, or received any of our kits as a gift for Christmas, then you saw something like this:

This was a huge step for us and we’re thrilled with how they turned out. It was exactly a year ago that I spent most of the holiday break learning about box design, creating dielines and cutting out several prototype iterations with a utility knife. After a few weeks of proofing, the full order arrived over the summer, and we transitioned to the new boxes during the month of October.

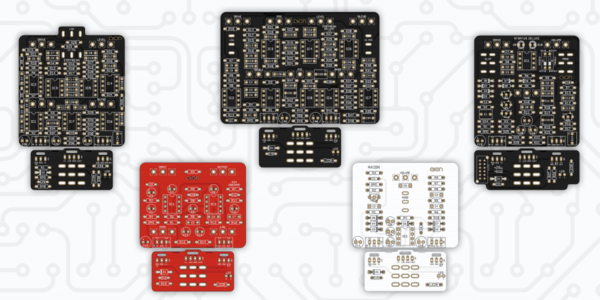

Along with this, we switched over to matte black PCBs for nearly all of our kits, with the Boss kits as the exception since the PCBs match the unique enclosure colors. As a practical matter, it helps us keep the inventory separate since several of the kits use slightly-tweaked versions of the standard PCBs. But it also just matches with the aesthetic a lot better since the new boxes are also black & gold.

Stickers & picks

Speaking of black and gold… we also designed stickers and guitar picks this year, and during the sale we sent them out with most of the kit orders. Here’s how those turned out:

Going forward, we may only include these with first-time kit orders (and subject to availability)—but we’ve added the stickers and picks to the store in case you want more.

Tariffs & global trade

The tariff situation in the United States has mostly stabilized after a volatile summer, but we’re still paying around 55% tariffs on most of our parts that come from China. We put in some sizable orders before the tariffs went into effect in April, so we expect to be cost-insulated on most parts for at least another year. As a result, tariff-related price increases have been very minor so far.

We’ll have a large enclosure order in spring or summer, so if the tariffs are still at their current rate once those arrive, we’ll see another small price adjustment. But a lot can happen between now and then, and if our costs don’t go up then our prices won’t either.

For the big picture on tariffs and how they’re impacting the guitar pedal industry, Fortune published an excellent article over the summer where they profiled Keeley, JHS, Cusack and Earthquaker Devices about the effect of the tariffs on their respective businesses. (If the article is paywalled, here’s an archived version.)

We’re a much smaller operation than any of them, but our experience is the same: it’s not that China is cheaper, it’s that most of the parts we use do not have domestic sources at all.

Jon Cusack also wrote a widely-shared Facebook post in October, crunching the numbers on what it would look like to spin up a factory to produce the SMD resistors that his company currently sources from China in high volumes and for which there is currently no USA-based alternative. He concludes that once this factory was up and running, the per-resistor cost would be a minimum of 10 times what he’s paying from China, even factoring the tariffs. Without a long-term bipartisan strategy that includes significant infrastructure investment, there’s just no viable path to reshoring production of these components.

WIMA capacitor shortage

Early this year, WIMA abruptly discontinued most of their 50V film capacitors. The 1uF types are 40% thinner than the standard ones from other manufacturers, and 139 of our projects were designed around these specific capacitors, so it quickly became a very big problem.

We wrote a pretty long article about it in November, so we’ll just crosslink it from here if you’re interested. We started stocking our own, and the Kemet replacements have just arrived at Mouser this week.

Over the summer we modified the layouts of 89 of our projects to add space for larger capacitors, although many of them are a couple years away from production since we have to get through the existing inventory first. The other 50 either already had enough space for the larger capacitors or else the layouts were too tight to add space.

For new designs, we’ll use 5mm-width capacitors whenever possible so the layouts are future-proof. Some projects are still going to use them if there’s no alternative (WIMA does expect to have them back in production eventually) but we’ll be as accommodating as possible.

USPS rate increases

We’ve shipped almost exclusively via USPS throughout the life of the company, but after some significant rate increases this year (especially for priority mail), UPS is now really competitive—in many cases, as much as 30-40% cheaper for domestic packages. We’ve been working on a live-rates shipping feature for the checkout, so you’ll be able to choose from a few different shipping options based on cost and preference. This will go live sometime in the next few months.

Project development

All of the above, both the good and the bad, had one thing in common: they took up a lot of time. As a result, 2025 had the fewest new releases of any previous year I can remember, with only six kits and five new PCBs. Maintaining what we have is always higher priority than creating new things, and this year the maintenance has been demanding. But I’ve missed project development, and am hoping to turn that around this coming year.

Sincerely, not a day goes by without Amanda and I reflecting on how grateful we are that we get to do this. When I was first getting started in building pedals, and failing my first several pedal attempts, I never would have guessed that this is where I’d be fifteen years later, much less that she would get to do it too. It’s you—our customers and the wider DIY community—that make it possible.

Here’s to an exciting 2026!

Kevin & Amanda VandeKrol